Until one starts sourcing PCBs for their ongoing manufacturing needs, one may not fully understand the complexities involved in the sourcing process. There are multiple steps in the PCB sourcing process. It starts with PCB prototype design and building and it ends with PCB assembly and testing. Each stage of the PCB testing process has its own challenges. In this article we will focus specifically on the challenges that are specific to the PCB assembly process.

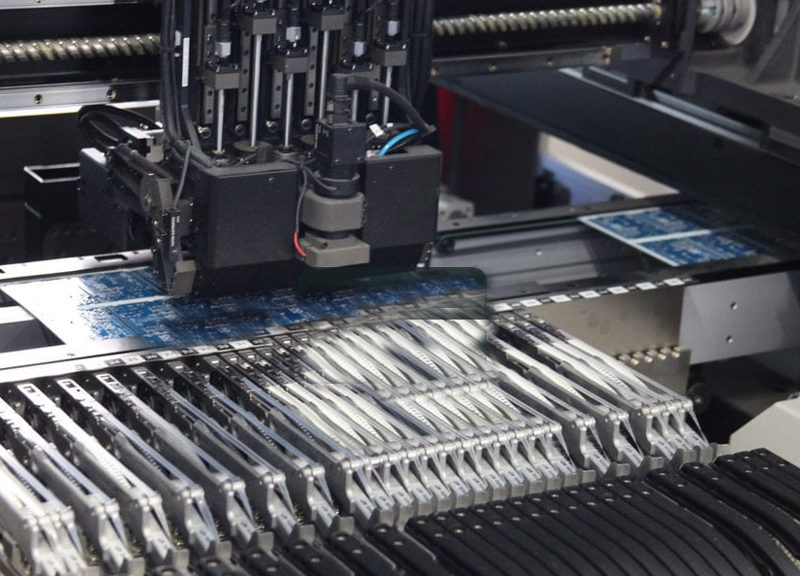

After the circuit boards are printed, the PCB components should be installed. The PCB assembly process could turn out to be a complex process because each PCB will have numerous components. Only after sourcing all the components, it is possible to complete the PCB assembly process. Even if a single resistor or capacitor is out of stock then your PCBs cannot be fully assembled and it could delay you production cycle.

Depending on the complexity of the PCBs required for your equipment the number of components will vary. Depending on the overall order volume, the volume of the components to be sourced will vary. Availability of all the components in adequate quantities could prove to be a difficult challenge. If you do not have access to the right sourcing network, you will face problems with every batch of PCBs.

Most customers entrust their PCB component sourcing needs too to their PCB manufacturing companies. They will have access to large networks from where they source their PCB components regularly. You may not have ready access to such networks at least initially and until then sourcing the PCB supplies will be difficult. It is not only about the availability of the PCB components, but it is also about the cost of the PCB components sourced. When a PCB manufacturer sources the PCB components, they will be sourcing in bulk quantities which will give them access to lower prices. You may not have access to such prices when you approach the suppliers for your requirements. You could eventually end up spending much higher prices for the PCB components. To avoid increasing your PCB production costs, you should try to access the lowest quotes possible for you PCB components or else, you will end up increasing the overall PCB production costs.

Along with the above concerns of PCB components availability, PCB components cost, we should also take cognizance of the PCB component quality. The overall quality of the PCB will depend fully on the components used. You will therefore be required to do a careful review of the suppliers of the PCB components.

All the above challenges could be avoided by selecting the best PCB manufacturing companies that offer end to end PCB manufacturing services. You will definitely be happy with the overall PCB sourcing experience when you select the most dependable PCB manufacturer that offers end to end PCB manufacturing solutions that also covers the PCB components sourcing within the quote given. Look for a China PCB manufacturer and you will save a lot of money.

ChinaPCBOne Technology LTD. is the author of this article on PCB assembly. Find more information, about PCB prototype.